What Can a Concrete Scanner Scan

What Can a Concrete Scanner Detect?

Concrete scanners, powered by ground penetrating radar (GPR) technology, are invaluable tools for imaging and analyzing features within concrete slabs. They are widely used in construction, engineering, and forensic applications to locate objects, assess structural integrity, and avoid costly mistakes during renovations or drilling. However, the success of a concrete scanner depends on three critical factors:

Three Critical Factors That Determine Concrete Scanning Success

The effectiveness of a concrete scanner depends on three primary factors: material contrast, object size, and depth. These factors influence how well the GPR signal interacts with the target and whether it can be detected and interpreted accurately. Let’s explore each factor in detail with real-world examples.

1. Material Contrast

Material contrast refers to the difference in electrical properties between the object being scanned and the surrounding concrete. GPR works by transmitting electromagnetic pulses into the concrete and analyzing the reflections that occur when the signal encounters a boundary between materials with different properties. The greater the contrast, the stronger the reflection and the easier it is to detect the object.

- Highly Reflective Materials:

- Metal: Metal is one of the most reflective materials for GPR because it is highly electrically conductive. For example, rebar, post-tension cables, and metal conduits within a concrete slab produce strong, clear reflections, making them easier to detect.

- Example: A contractor scanning a concrete slab to locate rebar before drilling will more likely see distinct, sharp reflections in the GPR record, allowing them to avoid damaging the reinforcement.

- Moderately Reflective Materials:

- Water and Moist Clay: Water-filled cracks or voids in concrete are detectable because water has a much higher dielectric constant than concrete. Similarly, moist clay soil filling a crack or void can create a detectable response.

- Example: During a structural inspection, a GPR scan reveals a water-filled void beneath a concrete slab, indicating potential subsidence or instability.

- Poorly Reflective Materials:

- Granite or Dry Sand: Materials that closely resemble concrete in their electrical properties, such as granite or dry sand, are harder to detect because they, generally, do not create a strong enough contrast to reflect the GPR signal effectively.

- Example: A forensic investigator attempting to locate the bottom of a concrete slab resting on dry sand may struggle to detect the interface due to the similarity of the sand to the host material.

Key Takeaway: The more the target material differs from concrete in its electrical properties, the easier it may be to detect. Metal and water are excellent targets, while materials like granite or dry sand are more challenging, within concrete.

2. Object Size

The size of the target is another critical factor in concrete scanning. For an object to be detected, it must be large enough to reflect a measurable amount of the GPR signal. Smaller objects may not produce a strong enough response, especially if they are buried deep within the slab.

- Small Objects Near the Surface:

- Example: A 1-inch diameter steel rebar located within the first 8 inches of the surface of a concrete slab may be detectable because the GPR signal does not have to travel far, and the rebar is large enough to reflect the signal.

- Real-Life Scenario: A structural engineer uses GPR to locate rebar near the surface of a concrete column to ensure proper placement before drilling.

- Small Objects at Greater Depths:

- Example: The same 1-inch diameter steel rebar buried 18 inches deep may not produce a detectable response under typical conditions because the signal weakens as it travels through the concrete, and the rebar is too small to reflect enough energy back to the receiver.

- Real-Life Scenario: A contractor scanning for reinforcement in a thick concrete slab may miss smaller rebar located at significant depths due to signal attenuation.

- Large Objects:

- Example: A large -inch PVC pipe or a metal conduit buried deep within a concrete slab is more likely to be detected because its size allows it to reflect a stronger signal.

- Real-Life Scenario: A construction team scanning for utility lines beneath a parking garage slab successfully identifies a large water pipe buried 18 inches deep.

Key Takeaway: Larger objects are easier to detect, especially at greater depths. Small objects may only be visible if they are close to the surface.

3. Depth

Depth plays a significant role in the success of concrete scanning. The deeper an object is buried, the harder it is to detect because the GPR signal weakens as it travels through the concrete. This weakening occurs due to absorption and scattering of the signal.

- Shallow Targets:

- Example: A rebar grid located 2 inches below the surface of a concrete slab is more easily detected because the GPR signal has minimal distance to travel and retains most of its energy.

- Real-Life Scenario: A contractor scanning a concrete floor for rebar before coring sees a clear, consistent pattern of reflections in the GPR record, indicating the rebar’s location.

- Deep Targets:

- Example: A post-tension cable buried 24 inches deep may produce a weak or no response, especially if the concrete contains dense reinforcing materials that scatter the signal.

- Real-Life Scenario: A structural engineer scanning a thick concrete bridge deck struggles to detect deeply buried cables due to interference from multiple layers of rebar.

- Interference from Other Materials:

- Example: A gravel base beneath a concrete slab can scatter the GPR signal, making it harder to detect the interface between the slab and the base.

- Real-Life Scenario: A team measuring the thickness of a concrete slab finds the bottom reflection unclear due to the rough, uneven surface of the gravel base.

Key Takeaway: Shallow objects are easier to detect, while deeper objects require stronger signals and may be obscured by interference from other materials.

How These Factors Work Together

The success of a concrete scan often depends on the interplay between material contrast, object size, and depth. For example:

- High Contrast, Small Size, Shallow Depth: A small metal conduit near the surface is more easily detected because metal reflects well, and the shallow depth minimizes signal loss.

- Low Contrast, Large Size, Deep Depth: A large void filled with air at a significant depth may still be detectable because its size compensates for the low contrast and depth.

- Low Contrast, Small Size, Deep Depth: A small plastic pipe filled with distilled water buried deep within a slab is unlikely to be detected due to low contrast, small size, and significant signal weakening.

Examples of Real-World Scenarios

- Locating Rebar in a Concrete Slab:

A contractor scans a concrete floor to locate rebar before drilling anchor holes. The rebar, made of metal, produces strong reflections, allowing the contractor to map its location and avoid damaging it during drilling. - Detecting a Water Leak:

A maintenance team uses GPR to locate a water-filled void or saturated soils beneath a concrete slab. The high contrast between water and concrete makes the void easier to detect, helping the team identify the source of the leak. - Measuring Concrete Thickness:

An engineer scans a concrete bridge deck to measure its thickness. The GPR signal reflects off the interface between the concrete and the base material, providing a depth estimate. - Identifying Private Utility Lines:

A construction crew scans a parking lot slab to locate buried private utility lines. Metal conduits and large PVC pipes filled with water are detected, allowing the crew to avoid damaging them during excavation. - Forensic Investigation:

Law enforcement uses GPR to search for a weapon hidden in a concrete wall. The metal weapon produces a strong reflection, making it easy to locate.

Conclusion

The success of a concrete scanner depends on the interplay of material contrast, object size, and depth. When compared to aged concrete, high contrast materials like metal and water are easier to detect, while low contrast materials like granite or dry sand pose challenges. Larger objects are more detectable than smaller ones, especially at greater depths. Proper planning, skilled operation, and understanding these factors are essential for accurate and reliable results.

By considering these critical factors and their real-world implications, GPR concrete scanning can be a powerful tool for construction, engineering, and forensic applications.

Real-World Applications of Concrete Scanning

Concrete scanners are versatile tools that can detect a wide range of objects and features. Below are some common applications:

1. Metal Objects

- Examples: Conduits, electrical wires, rebar, post-tension cables, and mesh.

- Performance: Metal is highly reflective and one of the easiest materials to detect with GPR. Even small metal objects can produce strong signals, making them visible at greater depths compared to non-metallic materials.

- Challenges: Multiple layers of metal or spatially dense materials like sheet metal can create interference, making it difficult to differentiate between objects. For example, overlapping rebar or wire mesh may produce a cluttered GPR record, complicating interpretation.

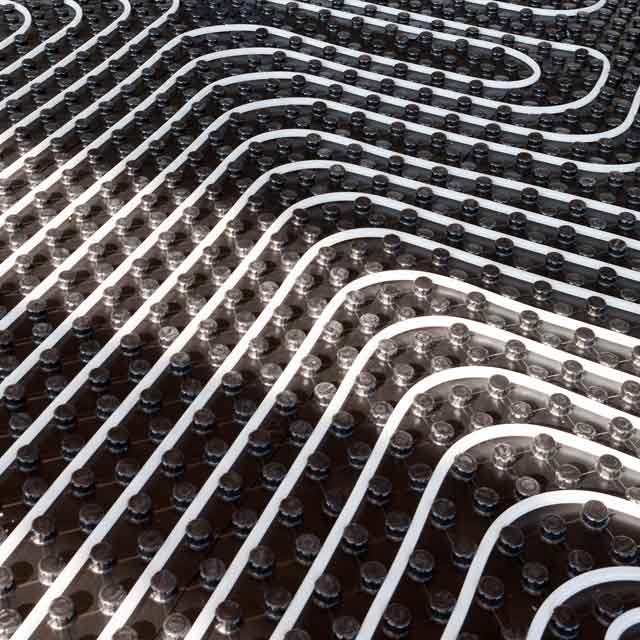

2. Fluid-Filled Pipes and Tubing

- Examples: PVC pipes, radiant heat tubing, and plastic pipes.

- Performance: While less responsive than metal, fluid-filled pipes and tubing are often detectable, especially if the fluid inside is conductive, such as saltwater.

- Challenges: The size and depth of the pipe play a significant role in its visibility. Pipes filled with fluids that have similar electrical properties to concrete, such as distilled water, may be harder to detect.

3. Voids and Air-Filled Spaces

- Examples: Voids, PVC pipes, and air pockets.

- Performance: Air-filled voids are detectable if they are large enough to reflect the GPR signal. The size of the void is critical, as smaller voids may not produce a strong enough response.

- Challenges: Need closely spaced lines and interference from concrete thickness, reinforcing materials, or uneven surfaces can obscure the response from voids.

4. Concrete Thickness

- Performance: GPR can measure the thickness of a concrete slab by detecting the reflection from the interface between the concrete and the base material beneath it.

- Challenges: The type of base material affects accuracy. For example, a well-compacted gravel base may blend with the slab, while a clay-rich base provides a clearer reflection. Uneven or rough surfaces can scatter the signal, making it harder to interpret.

5. Drain, Waste, and Vent Pipes (DWV)

- Performance: DWV lines are often detectable, but their depth can pose challenges. GPR may indirectly locate these lines by identifying the trench they were buried in, provided the signal penetrates deep enough.

- Challenges: DWV lines often slope to maintain proper drainage, meaning one end may be significantly deeper than the other. This depth variation can make it harder to detect the line directly.

6. Weapons, Evidence, and Bodies

- Examples: Guns, knives, and voids from bodies.

- Performance: Metal weapons are highly responsive and easy to detect if within the slab. Bodies or voids within the concrete may also be visible, but objects buried beneath the slab are outside the scope of concrete scanning.

- Challenges: Depth and interference from other materials can complicate detection.

7. Precious Metals and Coins

- Examples: Gold, silver, and coins.

- Performance: Precious metals respond well to GPR, but small items must be nearer to the surface to be detected.

- Challenges: Interference from wire mesh or other structural metals can obscure the response from small metallic objects.

Challenges in Concrete Scanning

While GPR is a powerful tool, certain conditions can affect its performance:

- Obstacles: Walls, equipment, or structures can limit access and create ambiguous results. For example, scanning along the baseboard of a wall may produce unclear data due to insufficient separation between the wall and the target.

- Interference: Steel fibers, corrugated decking, or dense reinforcing materials can obscure targets by creating overlapping signals.

- Concrete Properties: Newly poured or unusual concrete mixes may absorb signals, reducing their effectiveness. For example, wet concrete or concrete with high moisture content can weaken the GPR signal.

Best Practices for Concrete Scanning

To maximize the effectiveness of a concrete scanner, consider the following:

- Proper Planning: Understand the site conditions and potential obstacles before scanning.

- Skilled Operation: Ensure the operator is trained to interpret GPR data accurately.

- Equipment Configuration: Use the appropriate antenna frequency for the target depth and size. Lower frequencies penetrate deeper but provide less detail, while higher frequencies offer better resolution for shallow targets.

- Data Collection: Collect data systematically, using grids or parallel lines to ensure comprehensive coverage.

Conclusion

Concrete scanners are highly effective tools for detecting a variety of objects and features within slabs, from rebar and pipes to voids and slab thickness. However, their success depends on material contrast, object size, depth, and real-world conditions. While challenges like interference and obstacles can complicate results, proper planning, skilled operation, and understanding the limitations of GPR can help ensure accurate and reliable outcomes.

Whether you’re a contractor, engineer, or forensic investigator, GPR concrete scanning provides a nondestructive, efficient, and versatile solution for imaging what lies beneath the surface.