GPR Concrete Scanner and 3-D Imaging Services NDT

GPR Concrete Scanning Services for Nondestructive Testing

Nondestructive Testing (NDT) for Concrete Structures

Ground-penetrating radar (GPR) concrete scanning is a safe and effective method for imaging post-tension cables, conduits, pipes, wires, rebar, voids, mesh, tubing, and concrete thickness. Similar to X-ray but without the risks of nuclear radiation, GPR technology uncovers what lies inside concrete slabs by creating detailed 2D and 3D images or maps.

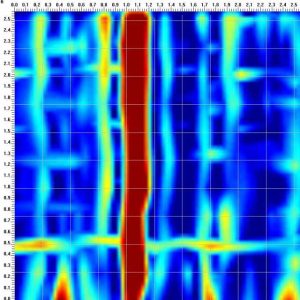

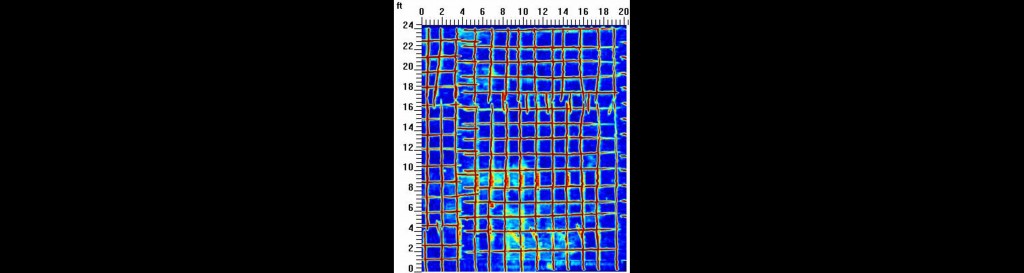

Using grids of parallel and perpendicular scan lines, GPR generates cross-sectional views that are processed into plan-view color maps. These diagrams can provide a clear record of the interior structure of concrete slabs, useful for immediate decision-making or long-term archiving and more detailed post processing. With a penetration depth of less than two feet, GPR is a reliable and nondestructive solution for concrete analysis.

In this guide, we’ll explain:

- What concrete scanning is

- The benefits of concrete scanning

- The professional services we provide

- How you can rent or train to use concrete scanners yourself

What is a concrete scanner? What is concrete scanning?

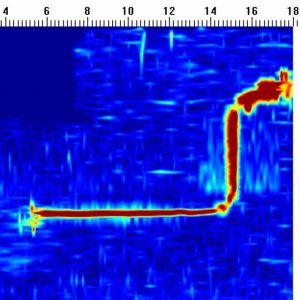

A concrete scanner uses ground-penetrating radar (GPR) technology to map and image the interior of concrete slabs. GPR equipment transmits electromagnetic pulses that reflect off objects within the concrete, much like a fish finder detects fish or a lake bottom. These reflections create detailed images, helping professionals locate and identify features with precision.

Concrete scanning is essential for detecting:

- Post-tension cables

- Conduits and wires

- Reinforcing bars (rebar)

- Metal pipes and plastic tubing

- PVC pipes, voids, and cracks

- Wire mesh and even precious metals (gold and silver)

Beyond Concrete: Versatility of GPR Scanning

GPR technology isn’t limited to concrete. It can also image features within materials like:

- Pavement

- Wood

- Asphalt

- Rock

- Ice

While X-ray scanning and handheld scanners are available, they often lack the versatility and functionality of a professional GPR concrete scanner.

Learn More or Get in Touch

Want to dive deeper into the theory and physics behind GPR technology? Click here to learn more.

Need a professional concrete scanner in Wisconsin, Illinois, Michigan, Indiana, Iowa, or Minnesota? Contact us today to get started!

Looking into training and renting a concrete scanner? Look no further.

Why use GPR to scan concrete slabs?

How GPR Stands Out Among Nondestructive Testing (NDT) Methods

When it comes to nondestructive testing (NDT) of concrete, several options are available, including X-ray, handheld concrete detectors, thermal imaging cameras, and rebar detectors. However, ground-penetrating radar (GPR) offers distinct advantages that make it the preferred choice for professionals.

Key Benefits of GPR Concrete Scanning

- Mapping and Imaging

GPR creates detailed 2D and 3D maps of concrete slabs, providing a clear visual representation of features like post-tension cables, conduits, rebar, voids, and cracks. Unlike small handheld detectors with limited displays, GPR’s comprehensive mapping and post processing capabilities increases confidence and reduces the risk of errors during cutting or drilling. - Permanent Records

GPR scans produce plan-view maps or 2D images that serve as permanent documentation. These records demonstrate why specific areas were marked for penetration and can help identify mistakes if directions weren’t followed. - Depth and Detection

GPR may penetrate up to 24 inches into concrete, far exceeding the capabilities of less expensive tools, which often only detect features a few inches deep. Additionally, GPR is often effective at detecting non-metallic features, such as plastic pipes or voids, which are challenging for other methods. - Safety Advantages Over X-Ray

Unlike X-ray, which uses radioactive materials and requires clearing areas for safety, GPR transmits safe electromagnetic pulses. GPR only needs access to one exposed face of the concrete slab, making it more practical for use during normal business hours without disrupting operations. - Large Area Scanning

GPR systems can scan large areas without the size limitations of X-ray film. They also provide real-time depth estimates, allowing professionals to differentiate between targets and assess their relative positions within the slab.

Limitations of GPR Concrete Scanning

While GPR is highly effective, it does have some limitations:

- Metallic Surfaces: GPR signals cannot penetrate metal-covered surfaces.

- Moisture and Uncured Concrete: Wet or uncured concrete absorbs the signal, reducing GPR penetration.

- Complex Targets: Characterizing corrosion, measuring rebar diameters, or mapping void thickness can be challenging due to the complexity of signal propagation.

- Air Gaps: Layers of wood, foam, or uneven surfaces create air gaps that reduce scanning accuracy.

Does GPR Concrete Scanning Work?

Absolutely. High-quality GPR equipment, when used correctly in suitable environments, delivers reliable results. However, success depends on the operator’s expertise and the effort put into the survey. Rushed scans or unrealistic expectations can lead to disappointment. GPR is a sophisticated tool governed by the laws of physics, not magical x-ray vision or a “crystal ball.”

Challenges in Void Detection

Locating voids beneath concrete slabs is possible, but determining their thickness is more complex due to how GPR signals propagate through hollow spaces. Similarly, imaging regions adjacent to hollow blocks or precast concrete can be difficult, as the contrast between the solid mass and hollow spaces can complicate the analysis and interpretation of the results.

By choosing GPR for concrete scanning, professionals gain access to a safe, versatile, and highly effective tool for mapping and imaging concrete slabs. While it has limitations, its advantages far outweigh those of other NDT methods, making it the go-to solution for accurate and reliable results.

The Importance of Expertise in Concrete Scanning

Why the Personal Approach Matters

Successful concrete scanning depends not only on advanced geophysical instrumentation but also on the expertise and approach of the operator. A skilled geophysicist or concrete scanner must design GPR surveys tailored to site conditions and the client’s desired level of confidence. Clients must understand and accept the physical limitations of GPR technology. When this collaboration is achieved, GPR often locates private facilities, measure concrete thickness, find voids, and detects post-tension cables, PVC pipes, and rebar.

A Message to Estimators and Proposal Writers

Concrete scanning with GPR is highly effective, but choosing the right provider is critical. When preparing a bid or budget, ensure you select a concrete scanner who offers:

- Cost-effective services

- A high level of due diligence

- Professional expertise with post processing capabilities

Professional concrete scanners often work directly with architects, engineers, and upper management, rather than as part-time tradespeople or concrete cutters.

The Two Types of Concrete Scanners

- Professional Concrete Scanners

- Charge $1,000–$3,000 per day.

- Provide detailed deliverables, including written reports and color-coded 3D graphics.

- Focus on accuracy and thoroughness, ensuring confidence in the results.

- Supplementary Concrete Scanners

- Charge $300–$500 per day.

- Often part of a construction or concrete cutting business.

- Provide basic cross-sections without 3D imaging or post processing, relying on 2D scan lines that can be difficult to interpret.

While both groups have good intentions, the second group often prioritizes speed over precision, which can lead to errors and undermine the credibility of GPR technology.

Why Professional Services Matter

Professional concrete scanners charge higher rates because they focus on delivering accurate, reliable results. Their fees reflect the value of their expertise, equipment, and the time required to produce detailed reports. In contrast, lower-cost providers may use concrete scanning as a way to secure contracts for other services, such as cutting or installing new lines. This approach can compromise the quality of the scan and lead to costly mistakes.

Questions to Ask Before Hiring a Concrete Scanner

- Does the scanner have experience with the theory behind GPR?

- Are they a geophysicist, engineer, or other qualified professional?

- Can they provide post processing, detailed reports, and 3D imaging?

GPR Concrete Scanning and 3D Imaging Services

Find a Trusted Concrete Scanner

For your next survey, contact Arthur Fromm, a licensed professional geologist and geophysicist with over 900 geophysical surveys conducted since 1985.

Regional Availability: Concrete scanning services are offered in Wisconsin, Illinois, Michigan, Indiana, Minnesota, and Iowa. Find a local provider who prioritizes accuracy and professionalism

Why Choose Geophysical Services LLC for Concrete Scanning?

With over 40 years of experience, Geophysical Services LLC has been a trusted provider of professional GPR concrete scanning services since 1985. Serving the Midwest, including cities like Chicago, Milwaukee, Madison, Green Bay, and Minneapolis, we deliver accurate results at competitive prices.

Our advanced equipment can scan entire rooms or small, isolated areas, making it ideal for a variety of applications, including:

- Locating post-tension cables, pipes, conduits, wiring, and rebar.

- Imaging difficult targets like bolts, plastic pipes, braided PVC tubing, voids, and cracks.

- Detecting sewer waste lines beneath gravel bases under favorable conditions.

Case Study: Precision Scanning for Core Drilling

In one project, nearly 60 core holes were drilled for decorative lighting on a 7×7-foot observation platform with closely spaced rebar. Thanks to our precise scanning, only two holes intentionally intersected the rebar, preserving the slab’s structural integrity.

The Geophysical Services Advantage

- Experienced Operators: Skilled professionals ensure accurate results.

- Reliable Equipment: Well-maintained GPR systems minimize downtime.

- Comprehensive Coverage: From small areas to entire rooms, we’ve got you covered.

Whether you need to locate critical features or preserve the integrity of your concrete structure, Geophysical Services LLC is your trusted partner for GPR concrete scanning.

Contact Art Fromm at Geophysicals Services LLC:

Phone: 262-242-4280

Email: info@concretescanner.com

Rentals and Training: Empowering You to Do It Yourself

Why hire an expensive GPR (ground penetrating radar) service franchise when you can save money, gain skills, and take control of your projects? At ConcreteScanner.com, we offer affordable GPR equipment rentals and a hybrid training program to help contractors, engineers, and professionals perform their own concrete scans with confidence.

Why Choose Rentals and Training?

By renting equipment and learning with us, you’ll:

- Save Money: Renting and training is far more cost-effective than hiring third-party services.

- Gain Independence: Learn the skills to perform GPR scans yourself, eliminating reliance on outside providers.

- Enjoy Flexibility: Rent equipment only when you need it, avoiding ownership and maintenance costs.

Our GPR Equipment Rentals

We offer two industry-leading scanners:

- Noggin 1000 MHz SmartCart/SmartHandle: Ideal for large areas and versatile configurations.

- TR1000/Conquest Concrete Scanner: Compact and perfect for tight spaces or vertical surfaces.

Not sure which scanner is right for you? Contact us to find the best fit for your project!

Hybrid GPR Training Program

Our hybrid training program combines online learning with hands-on practice to help you become better prepared to scan concrete.

How It Works:

- Learn Online: Complete a manufacturer-approved GPR certification course from Sensors & Software.

- Practice In-Person: Gain hands-on experience with the Noggin or TR1000 scanners at our facility or yours.

- Scan with Confidence: Use your new skills to tackle projects like rebar detection, conduit mapping, and structure.

Who Benefits from Rentals and Training?

Our program is perfect for:

- General Contractors: Avoid costly mistakes and ensure structural integrity.

- Utility Locators: Locate conduits and pipes with GPR.

- Engineers and Surveyors: Map rebar patterns and measure slab thickness.

- Renovation Specialists: Add a layer of safety when cutting and coring concrete in older buildings.

Get Started Today

Take control of your projects with our rentals and training program.

Contact Nate of K.D. Jones Instruments Corp. / Geophysical Equipment Rental LLC:

Phone: 262-442-6745

Email: nate@kdjonesinstruments.com

Milwaukee

Green Bay

Madison

Appleton

La Crosse

Beloit

Superior

Platteville

Wausau

Chicago

Rockford

Waukegan

Peoria

Champaign

Springfield

Kankakee

Bloomington

Joliet

Aurora

Marquette

Escanaba

Menominee

Iron Mountain

Sault Ste. Marie

Houghton

Grand Rapids

Mackinaw City

Marinette

Traverse City

Kalamazoo

Indianapolis

Gary

South Bend

Lafayette

Fort Wayne

Michigan City

Terre Haute

Minneapolis

St. Paul

Rochester

Duluth

Iowa

Dubuque

Clinton

Davenport

Prairie du Chien