Concrete Scanning Rentals and Training

Your Trusted Partner for Concrete Scanning Rentals and Training

Why hire an expensive GPR (ground penetrating radar) or concrete scanning franchise when you can save money, gain skills, and take control of your projects? At ConcreteScanner.com, we provide affordable GPR equipment rentals and a hybrid GPR training program that empowers contractors to perform their own concrete scans. By renting and learning with us, you’ll:

- Save Money: Renting and training can be far more cost-effective than hiring a franchise, keeping more of your budget in your pocket.

- Gain Empowerment: Learn the skills to perform GPR concrete scanning yourself, giving you full control over hired contractors, your projects, and eliminating reliance on third parties.

- Achieve Better Results: Take the time to thoroughly survey your job areas, ensuring more accurate and satisfactory outcomes. Allows one to repeat or extend survey areas as needed.

- Enjoy Flexibility: Rent GPR equipment only when you need it, avoiding the overhead and maintenance costs of ownership.

We offer two industry-leading concrete scanners—the Noggin 1000 MHz SmartCart/SmartHandle and the TR1000/Conquest Concrete Scanner—to meet the unique needs of your project. Not sure which one is right for you? Let us help you decide.

Why Use GPR?

Adding ground penetrating radar (GPR) to your business is a smart investment that can prevent costly and dangerous mistakes before cutting or coring concrete. Here’s why:

- Protect Structural Integrity: Cutting through structural components like rebar or post-tension cables can weaken the structure and compromise its safety.

- Prevent Catastrophic Damage: Accidentally cutting an embedded conduit, gas pipe, or post-tension cable can result in severe damage, costly repairs, or even loss of life.

- Avoid Liability: Failing to scan concrete before cutting opens your firm and your customers to damage claims, safety hazards, and potential legal issues.

What Can GPR Do for You?

GPR concrete scanning is a powerful tool for concrete floor slab scanning and can help with:

- Mapping Structural Elements: Locate rebar, post-tension cables, wire mesh, and metallic or non-metallic pipes and conduits.

- Locating Conduits and Heating Lines: Identify plastic and metallic conduits, as well as in-floor heating lines in concrete or just below slab-on-grade.

- Measuring Cover Depth: Determine the depth to a target of interest to avoid accidental damage.

- Measuring Slab Thickness: Assess the thickness of concrete slabs for better planning and execution.

- Detecting Voids and Cavities: Identify voids and cavities beneath slab-on-grade to prevent structural issues.

By incorporating GPR technology into your workflow, you’ll ensure safer, more efficient, and more accurate results for your projects.

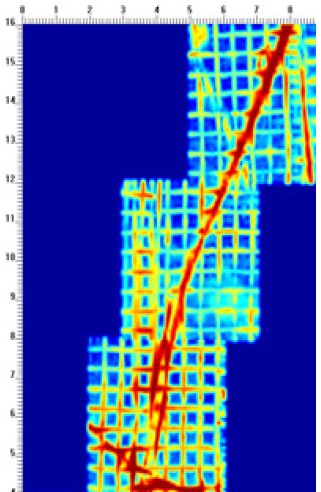

Meet the Noggin 1000 MHz SmartCart/SmartHandle

Versatile, Affordable, and Built for Large Areas

The Noggin 1000 MHz system is a high-resolution GPR scanner designed for shallow, detailed scans. Its modular design allows it to be configured as a SmartCart for large, open areas or as a SmartHandle for walls, ceilings, and tight spaces. This flexibility makes it a favorite among contractors who need a cost-effective, adaptable solution.

Noggin Pros

- Cheaper Rental Price: A budget-friendly option for contractors.

- Versatile Configurations: Use the stand alone SmartCart for large, open areas or the SmartHandle for tight spaces.

- High-Resolution Imaging: Perfect for locating small objects like rebar and post-tension cables.

- Customizable Scanning Modes: Tailor your scans with adjustable depth, gain, and grid settings.

- Durable and Portable: Lightweight and rugged for job site conditions.

Noggin Cons

- With older DVLs with Black and White Screen: Less user-friendly compared to modern color displays.

- No In-Field Data Post Processing: Data must be transferred to a computer for more detailed post processing, analysis, adding time to the workflow.

- Not Ideal for Small, Tight Spaces: While versatile, it’s not as compact as the TR1000 for confined areas.

Read the Noggin 1000 MHz SmartHandle Manual

Read the Noggin 1000 MHz SmartCart Manual

Meet the TR1000 / Conquest Concrete Scanner

Compact, Lightweight, and Perfect for Tight Spaces

The TR1000 / Conquest Concrete Scanner is a compact, all-in-one GPR system designed for ease of use. Its lightweight design and modern features make it ideal for scanning walls, overhead surfaces, and confined spaces. With a newer color DVL and in-field data processing capabilities, it’s perfect for contractors who value convenience and efficiency.

TR1000 Pros

- Compact and Lightweight: Perfect for tight areas and vertical applications.

- Newer Color DVL: Intuitive interface with real-time data visualization.

- In-Field Data Processing: Analyze results on-site without needing a computer.

- Ease of Use: Simple setup and operation with minimal configuration.

- Durable and Reliable: Built to withstand tough job site conditions.

TR1000 Cons

- Slightly More Expensive Rental Rate: Higher cost compared to the Noggin system.

- Possibly Less Efficient for Large Surveys: Its smaller size makes it more effort-intensive for large-scale projects.

- Limited Scalability: Lacks the modularity, ability to use multiple frequency antennas, of the Noggin system for complex surveys.

Read the pulseEKKO Manual possessing a dedicated TR1000/Conquest Concrete Scanner Chapter

Download the 2026 Sensors & Software Conquest Brochure

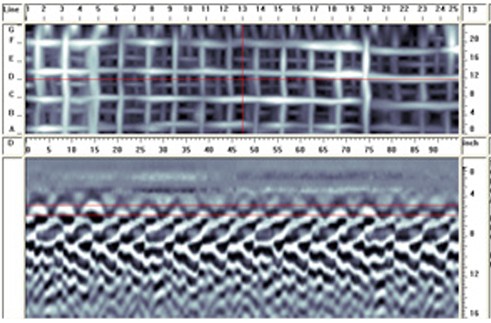

EKKO_Project GPR Software: Take Your Scans to the Next Level

Powerful Post-Processing for Accurate and Professional Results

After collecting your GPR data with the Noggin 1000 MHz SmartCart/SmartHandle or the TR1000/Conquest Concrete Scanner, the next step is to analyze and interpret your findings. That’s where EKKO_Project GPR Software comes in. This powerful post-processing tool is designed to help you turn raw data into actionable insights, turn your scans into a professional product and create a report.

Read the EKKO_Project User’s Guide

Who Benefits from GPR?

GPR concrete scanning is a game-changer for a wide range of industries, including:

- General Contractors: Avoid costly mistakes and improve structural integrity.

- Private Utility Locators: Locate conduits and pipes, often with great precision.

- Engineers and Surveyors: Map rebar patterns and measure slab thickness.

- Renovation Specialists: Increases safety for cutting and coring concrete in older buildings.

- HVAC and Plumbing Professionals: Locate in-floor heating lines and embedded pipes.

Frequently Asked Questions

Q: How deep can the scanners detect objects in concrete?

A: While site dependent, both the Noggin 1000 MHz and TR1000 are optimized for shallow scans, detecting objects up to approximately 24 inches deep in concrete. However, you may not always achieve maximum penetration depending on material, target composition, target size, and interference from other objects. 12 inches may be more realistic in most cases.

Q: How does the material, target composition, target size, and interference from other objects affect concrete scanning?

A: Several factors influence GPR penetration and target detection:

- Material: The type of material (e.g., concrete, asphalt) affects signal attenuation. Variations in concrete, such as water content, admixtures, and aggregate size, impact penetration. Wet concrete has higher electrical conductivity, reducing depth.

- Target Composition: Metal easily reflects GPR energy, making it highly detectable. Non-metallic objects reflect less energy, making them harder to detect.

- Target Size: Larger targets reflect more energy, making them easier to identify.

- Interference: Multiple embedded objects (e.g., rebar, conduits) can mask deeper targets, making it harder to analyze and interpret below the upper layers.

Understanding these factors helps optimize scanning techniques for better results.

Q: Do I need prior experience to use the scanners?

A: No previous experience is required for training. Our hybrid GPR training program will provide you with hands-on experience and a foundation for conducting surveys. With experience one improves.

Q: Can I rent the equipment without taking the training?

A: Yes, you can rent the equipment on its own. However, we highly recommend the training to ensure you get the most accurate and reliable results.

How to Rent with Us

Renting a concrete scanner is simple and hassle-free:

- Choose Your Scanner: Select the Noggin or TR1000 based on your project needs.

- Submit Required Documents: Provide a Certificate of Insurance (COI) and a completed credit card authorization form.

- Book Your Rental: Contact us to confirm availability and schedule your rental.

- Pick Up or Ship: Pick up your equipment or have it shipped to your location.

- Return the Equipment: Ship the scanner back or drop it off at our facility when your rental period ends.

K.D. Jones Instruments Corp. / Geophysical Equipment Rental LLC. Rental Requirements Form

From more information, contact K.D. Jones Instrument Corp /Geophysical Equipment Rental:

Email: nate@kdjonesinstruments.com

Phone: 262-442-6745

www.kdjonesinstruments.com

www.geophysicalequipmentrental.com

Take Your Training to the Next Level with Our Hybrid GPR Training Program

At ConcreteScanner.com, we don’t just rent equipment—we empower you to use it with greater confidence. That’s why we offer a hybrid GPR training program that combines the best of online GPR training and hands-on concrete scanning practice.

How It Works

Our hybrid GPR training program is designed to make learning both flexible and practical. Here’s how it works:

- Learn Online: Start with a manufacturer-approved GPR certification course from Sensors & Software. Learn directly from industry experts and earn a certificate that proves your skills in concrete scanning training and GPR technology.

- Practice In-Person: Once you’ve completed the online course, visit our facility to practice using the Noggin 1000 MHz SmartCart/SmartHandle or the TR1000/Conquest Concrete Scanner. Get hands-on experience with professional-grade equipment in a real-world setting.

- Scan with Confidence: With both certification and hands-on training, you’ll be better prepared to tackle your project with confidence, whether it’s GPR concrete scanning for rebar detection, conduit mapping, or void identification.

Why Choose Our Hybrid GPR Training?

Our hybrid GPR training program is designed with your success in mind. Here’s why it stands out:

- Manufacturer Certification: Gain credibility with a certificate directly from Sensors & Software, a trusted name in GPR technology.

- Hands-On Experience: Practice with the same GPR equipment you’ll rent for your projects, including the Noggin 1000 MHz and TR1000.

- Flexible and Convenient: Learn online at your own pace, then schedule your in-person session when it works for you.

- Save Time and Money: Avoid the high costs of hiring third-party scanning services by learning to perform concrete scanning yourself.

- Support: Our team is available to answer your questions and provide guidance every step of the way, making it easier for you to get the most out of your GPR training.

What You’ll Learn During Hands-On Training

During your in-person session, you’ll cover most of what you need to know to perform GPR concrete scanning:

- Equipment Setup: Learn how to assemble and configure the Noggin 1000 MHz SmartCart/SmartHandle or the TR1000/Conquest Concrete Scanner for different scanning scenarios.

- Survey configuration: Understand how to configure the equipment for better results.

- Scanning Techniques: Practice scanning walls, floors, and overhead surfaces to locate rebar, conduits, and other embedments.

- Data Interpretation: Learn many aspects on how to analyze scan results and identify structural elements, voids, and other features using GPR technology.

- Troubleshooting: Gain the skills to address common issues and ensure smooth operation in the field, increasing your confidence to handle challenges during your projects.

Ready to Get Started?

Whether you’re a seasoned contractor or new to GPR concrete scanning, our hybrid GPR training program will improve your skills and confidence to succeed.

- Enroll in Training: Visit sensoftu.com/plus/catalog/courses/152 to sign up for the online GPR certification course.

- Choose Your Scanner: Decide between the Noggin 1000 MHz SmartCart/SmartHandle and the TR1000/Conquest Concrete Scanner based on your project needs.

- Schedule Your Rental and Hands-On Session: Contact us to book your equipment and practice session.

Get a head start on your training. Download and read the Concrete Scanning with GPR Guidebook from Sensors & Software, Inc:

*Please note that this guidebook, course work, and training are to be used as a reference and not to be used in place of experience or expertise. Not all equipment may have the same features or functions found in this guidebook.

Contact Us Today to Reserve Your Scanner and training session!

Email: nate@kdjonesinstruments.com

Phone: 262-442-6745

www.kdjonesinstruments.com

www.geophysicalequipmentrental.com

Our hybrid GPR training program combines the flexibility of online learning with the practicality of hands-on experience, making you more fully prepared to perform concrete scanning with confidence.

Why This Works

- Comprehensive Learning: From online certification to in-person practice, you’ll gain a better understanding of GPR technology and its applications.

- Real-World Skills: Hands-on training helps to ensure you’re more ready to handle real-world challenges, from equipment setup to data interpretation.

- Cost-Effective: Save money by learning to perform GPR concrete scanning yourself, eliminating the need for expensive third-party services.

- Industry Credibility: A manufacturer-approved certificate from Sensors & Software adds credibility to your skills, creating you a path for making you a trusted professional in the field.

- Flexibility and Convenience: Rent equipment only when you need it, and learn at your own pace with our online and in-person training options.

- Enhanced Safety and Accuracy: With GPR technology and proper training, you can avoid costly mistakes, protect structural integrity, and help to ensure safer outcomes for your projects.

- Tailored Solutions: Whether you’re scanning large open areas or tight spaces, our range of equipment and training options ensures you have the right tools for the job.

By combining GPR training with expert support, we work to make it easier for contractors, engineers, and professionals to master concrete scanning technology and take control of their projects.